What Are Platform Scales: A Guide

Professionals use platform scales in several different industries, but what are they used for? How do they work? Check out this handy guide to learn more.

The global market for electronic weighing scales is worth approximately $4.6 billion. It’s a major industry that affects almost every other because it allows them to safely, efficiently transfer their cargo.

There are several types of weight measurement systems available today, from small retail scales used in stores to large industrial options. Choosing the right type is essential for your business.

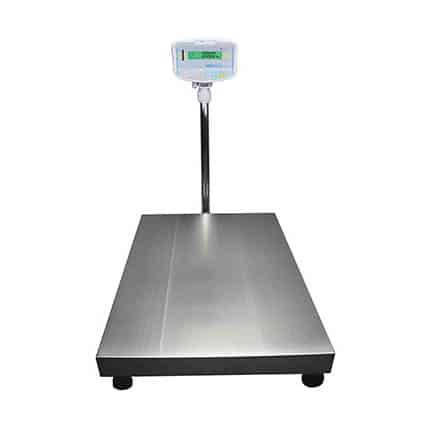

Platform scales are a durable option that can stand up to the dirtiest, harshest environments. They’re a convenient way to ensure that every vehicle leaving your facility hasn’t exceeded mass limits and has the right amount of cargo in its load. So when your vehicle gets to a weigh-bridge – you can be confident in easy passage, no fines and no delays.

Purchasing a platform scale is a worthwhile investment if you choose the right one. Read our guide to learn what platform scales do and how to find the best one for your needs.

What Are Platform Weighing Scales?

Industrial scales are used for industrial weight measurement. They’re rugged, durable, and can handle extreme weight capacities. This makes them perfect for environments such as warehouses, factories, mining sites, and industrial work sites.

There are 3 types of industrial scales; platform scales, pallet scales , and weighing scales.

Platform scales can weigh large, heavy, and awkwardly shaped loads. They support capacities of 1,000-3,000 kilograms. They use a simple, flat design.

Why Do I Need to Perform Weight Measurement?

Platform weighing scales have several benefits. They help forklift operators by allowing them to set their loads on the platform for quick, accurate weight measurements. They ensure you have the proper amount of product in every shipment and prevent mistakes.

One of the most important reasons you need platform scales is to prevent truck overloading. It’s dangerous and puts you at risk of severe legal and financial repercussions. Exceeding weight ratings damages your breaks. They may stop working due to the excess weight pushing down on them. Overloading a truck also increases the distance it takes for it to stop. This makes it hard to stop quickly in an emergency. Axle overloading is equally dangerous but is also one of the most difficult truck overloading issues to spot. It occurs when excess weight rests on one axle of the truck.

In serious cases, overloaded trucks can even cause a bridge or road to collapse. This puts everyone around the truck in danger.

How Can I Use Platform Scales to Prevent Overloading?

Truck overloading laws are intended to prevent these dangers. They require every vehicle on the road to meet mass limits or face severe penalties. To prevent overloading, you must first understand the differences between weight and mass.

Weight determines gravity’s pull on an object and varies by location. Mass stays the same and determines the amount of matter an object contains and its inertia. Truck overloading laws use mass to determine how heavy a truck and its load can be. The two types of mass limits trucks must meet include GMV, a measure of total mass, and axel mass, the mass carried on each axle.

Mass limits differ based on the type of vehicle, manufacturer recommendations, and spacing between the axles. This makes it difficult to determine a vehicle’s limits, but you can look them up from the National Heavy Vehicle Regulator or Road and Maritime Service.

Minor risk is 105% of the mass limit or less. Substantial risk is 105-120% of the mass limit. Severe risk involves weights 120% of the mass limit. Fines for truck overloading can’t exceed $22,000, but criminal and civil charges are also a possibility if the overload leads to property damage.

How Do I Choose a Platform Scale?

Platform scales are an essential part of any business that uses or sends heavy cargo regularly. It prevents overloading and speeds up daily operations. Don’t rush into the decision after deciding you need one of these helpful products. Begin by considering the scales themselves, then find the right supplier to purchase them from.

Finding the Right Scale

To choose the right platform scale, consider ease of operation, durability, and cleanliness.

Most weigh measurement operations occur at the end of a production process and need to be completed quickly. They should be easy to use to ensure you meet deadlines.

Harsh work environments require heavy-duty scales with high durability. You’ll need stainless steel surfaces and other protective measures.

Cleaning scales can be a time-intensive process, especially in processing facilities that handle large items that leave behind a residue. An IP-66 rated platform scale is easy to clean without causing damage.

Before buying, consider the type, material, location, warranty, calibration, and cost of the scale. An improperly calibrated scale won’t give accurate measurements. The process must be completed by a professional o make sure your supplier is technically competent and not just a retailer.

Placing your scales in the right location is essential. Consider the gradient of the slope, how much room vehicles will have to access the scale, the number of turning circles they’ll require to use it, and environmental factors such as potential flood sites. having done all this, you would also be well advised to weigh your vehicle before it leaves your premises. This is a great way to confirm that your platform scales have done their job but also that the right number of pallets have been loaded onto your vehicle.

Weighbridges are an excellent investment for hauler and soon become a critical path of operations so your weighbridge investment and should come with a warranty.

Find the best quality weighbridge you can for your budget. Cheap options aren’t as accurate or durable and come with shorter warranties. Remember to keep additional costs such as installation and maintenance in mind as well.

Finding the Right Supplier

There are several factors to consider before you choose a weighbridge supplier.

Begin by considering the maximum vehicle size your scales need to weigh. Larger vehicles and weights require larger weighbridges. Readability is also essential. It ranges from 0.01-0.1. The larger the number, the easier it will be to read your weight measurement data. Consider the solutions that the supplier offers. They should offer a wide range, and their products should be adaptable and customizable. They should also offer a full software suite that helps with weighbridge and batching plant requirements.

Research the company’s reputation. They should be known for offering quality products and customer service. Look for reviews online. Ask to see how their scales are designed, what components they use, and if they meet government standards.

The company should also offer you calibration and maintenance services.

Where Can I Find Platform Scales?

Platform scales are durable enough to last in almost any job site and powerful enough to provide accurate weight measurement data. Many suppliers offer these essential tools. Choosing the best one ensures you’ll get the data you need for years to come.

Weigh More has been a trusted weighbridge supplier for decades. Browse our platform scales today.