Mining operations are intricate processes that require meticulous attention to detail, particularly in the area of materials handling. Weighing Solutions play a pivotal role in optimizing these operations, ensuring efficiency, accuracy, and regulatory compliance. This article explores the spectrum of weighing solutions tailored for the mining industry, and the significant benefits they offer.

Importance of Accurate Weighing in Mining

Accurate weighing is paramount in mining operations. It facilitates precise extraction, processing, loading, transportation, and distribution of materials. Inefficient or inaccurate weighing can lead to losses, regulatory penalties, and operational bottlenecks. Therefore, mining operations invest considerably in advanced weighing solutions to ensure their processes are as accurate and efficient as possible.

Types of Mining Weighing Solutions

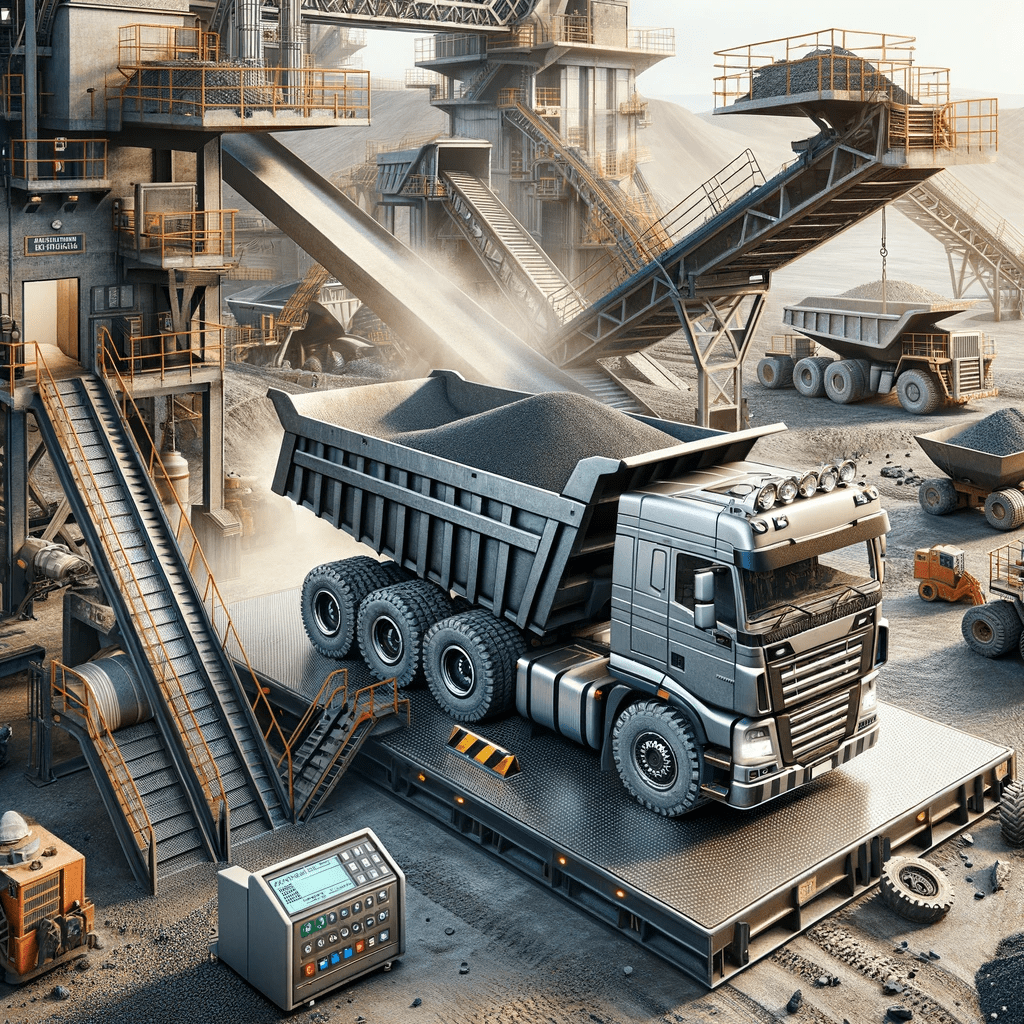

1. Weighbridges and Multi-deck Weighbridges:

Ideal for weighing heavy road vehicles and rail wagons, weighbridges ensure accurate measurements of massive loads. Multi-deck weighbridges are particularly useful in sites that weigh multi-trailer and axle groups, with each deck having its own digital weight indicator for total weight calculation.

2. Axle Weighers:

Axle weighers provide an economical alternative to full-length weighbridges. They weigh a single axle at a time and compile the weights to derive a total vehicle weight.

3. Wheel Weighers:

These are portable and can be relocated as needed. They require a flat, solid, and level surface for optimal performance.

4. Belt Weighers:

Belt weighers complement weighbridges by offering a solution for stock control. They are extremely accurate, subject to site conditions.

5. Weigh Bins and Hoppers:

These weighing solutions are ideal for managing a large range of products while being stored on-site. Most hoppers can be retrofitted with a weighing system.

6. End Loader Scales:

End loader scales weigh products at the point of loading, offering an approximate weight that helps with more accurate loading, reducing the need for reloading.

7. Onboard Vehicle Weighing:

Onboard vehicle scales provide accurate overall load readings and axle loads simultaneously, enhancing driver safety and preventing axle overloading fines.

Advantages of Weighing Solutions

Mining weighing solutions offer several advantages:

- Handling High Volume: They efficiently weigh thousands of tons, managing high volumes of materials.

- Accuracy and Consistency: They provide accurate and consistent readings, ensuring precise measurements for operational efficiency.

- Durability: They are designed to withstand harsh mining conditions, offering long-term reliability.

Technological Developments in Weighing

Technological advancements have significantly improved the functionalities of mining weighing solutions. Traditional scales, which required frequent calibration and maintenance, have been replaced with advanced weighing and scanning technologies like load volume scanners and portable truck scales.

Importance of Support and Service

Regular servicing of mining weight is crucial, especially when installed in harsh conditions. Preventive maintenance ensures smooth and accurate operation, minimizing equipment breakdowns and operational disruptions.

Conclusion

In mining operations, accurate and efficient weighing is a critical success factor. Advancements in technology have led to the development of robust and reliable mining weighing solutions that not only enhance operational efficiency but also ensure regulatory compliance. Investing in the right weighing solution is, therefore, a strategic decision that can significantly impact a mining operation’s bottom line.